Precipitated silica is manufacture with most modern machinery under controled of its physical and chemical properties

Special Feature

- Snowhite, free flowing powder

- Fine particle size

- High surface area

- Low bulk density

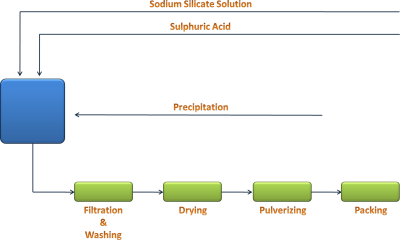

Process

There are so many varities of precipitation technique to manufacture precipitated silica.

In properties of silica can be used through change in

1) Concentration of reactants

2) Reaction Temperature

3) Reaction time

Applications of PPted silica

- PPted silica with high absoaptivitiy and relatively large particle size. It is recommended for insecticides, pesticides, weedicides, adhesive and emulation. It is also suitable for hose pipes, water repellent, rubber goods, cable, micro cellular sheets.

- High dispersibility makes it better reinforcing silica and suitable for filling in natural, symentic and latex rubber, transperent shoe soles, tyre tube, rubber lining, vulcanizers, rice rubber rolls, belting, footware.

- In the manufacture of transperent tooth paste and tooth powder, when silica is added to paste or tooth powder, it acts as a good abrasive agent, there by cleaning the teeth throughly. It gives denstering or flattering effect in paints, prevents settling of pigments, stabilizer emulation and helps to cover greater surface area. It is also suitable for cosmetics as a thickening agent and as an absorbent of natural oils. It is useful in thickening ink, heavy duty rubber tyre, grease & paper.

Packing

20/25 kg in HDPE laminated bag with inside liner for better protection.

Technical Information

| Color and appearance: Snowhite, free flowing, light powder. | |

|---|---|

| Particle Size-mμ | 10 – 25 |

| BET surface area – M²/gm | 120 – 260 |

| Moisture content at 105ºC for 1 hr-% max | 5 |

| Ignition loss at 1000ºC for 1 hr-% max | 11 |

| Bulk density – Gm/cc | 0.08 – 0.25 |

| PH 5% aqueous solution | 6.6 – 7.2 |

| Water Absorption | 160 – 260 % |

| Oil Absorption | 170 – 280 |

| Residue on 325 mess wet sieving – % max | 0.35 |

| Soluble Salt – % max | 0.5 |

| R2O3 – % max | 0.3 |

| SiO2 – % min | 88 – 90 |

| Specific Gravity | 1.95 |

| Refractivve Index | 1.46 |

The information and suggestive applications contained herein are given purely as a guide and the company does not undertake any responsibility for the results that may be delivered by the consuming industries.