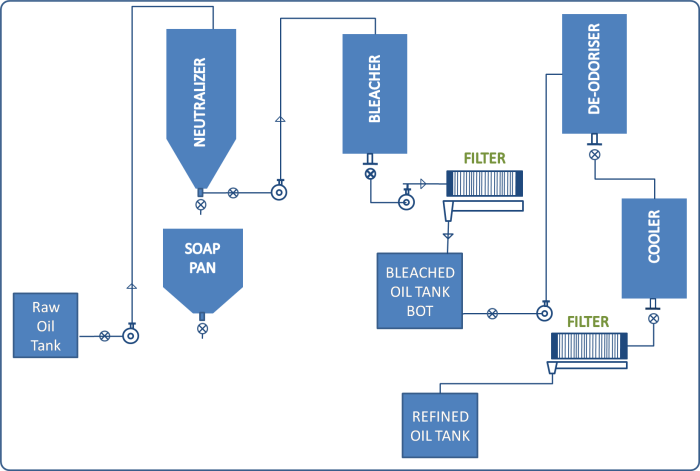

Most of all edible-cooking oils are contains gum. It is necessary to remove from oil. In neutralizer, oil is heated to 60-65ºC & add phosphoric acid 0.06-0.1% with continues stirring for ½ hour & then we can go neutralization process

Degummed oil is heated to 65-70ºC and required quantity of caustic soda solution is added slowly. The reaction is take place between free fatty acid and caustic soda solution and stirring is continues. Soap is formed. Then stirring is stop & soap will setteled down. This soap is remove and 3-4 hot water wash is required to remove soap and alkaly impurities. Oil is totaly neutral. Then we can use in bleaching process.

Neutral oil is heated to 110ºC and required quantity of activated bleaching earth powder and carbon is charged with constant stirring for 1 hour. Then oil is filter to remove spent earth powder. Then we can use in deodourising process.

In deodourising process, smell & fatty matter of oil is remove. Oil is heated 130ºC and open steam is applied and oil is heated upto 180-220ºC with constant open steam during 3-4 hour and oil is cooled and then filter to remove impurity. Oil is ready to use.

- Neutralizer

- Bleacher

- Deodourizer

- Cooler

- Filter Press

- Raw Oil Tank

- Neutral Oil Tank

- Bleaching Oil Tank

- Refined Oil Tank

- Soap Pan

- Thermic Fluid Boiler

- Steam Boiler

- Pipe line, Valve, Vacuum pump, Pump & Electric motor

Note:

- Refining of edible/cooking oil means to removes natural color and natural smell/odour and free fatty acid, volatile metal viscocity contains in the crude oil

- We can supply of oil refinery capacity like 5 MT, 10 MT, 15 MT, 30 MT per day or more.

- Erection & fitting of all required machineries are properly due to you can easily operating